Electro-Conductive Sockets

Electro-Conductive Sockets

These electro-conductive sockets conduct the electrical power needed for plating from the source to the plating device.

We produce anode or cathode sockets; the socket parts that conduct the electrical power are made of copper, or bronze, so that excellent conductivity is assured. Our electro-conductive sockets are able to conduct up to 8,000 A. We offer sockets with pneumatic or mechanical pressure. Some sockets allow the use of internal cooling, which contributes to longer service life and better power transmission.

In our range, there are electro-conductive sockets for three basic cathode and anode bar ends, or for plating drums: wedged, anode or circular (bar).

It is important to place an heat-resistant insulation pad under the electro-conductive socket during assembly. It should be kept in mind that any dirt in these sockets may lead to the creation of transient currents and overheating of the socket. In extreme situations where there is insufficient insulation, the bath could ignite, causing a fire!!

It is further recommended to lay a rubber pad under the heat-insulation one. This is needed for plastic baths whose upper edge is designed as a steel strut wrapped in plastic film. Thus, the space between the screw and its through-hole is sealed to prevent chemicals from flowing into the steel strut.

Regarding all possible problems, all the electro-conductive sockets must be regularly cleaned and greased with an electro-conductive mineral grease.

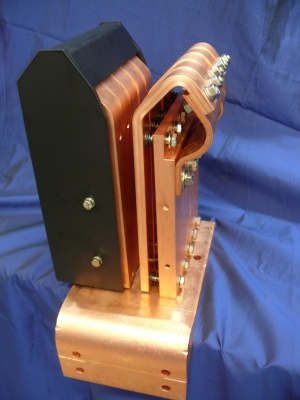

Knife-Type Mechanical-Pressure Socket

This socket is characterised by its simple design and relatively 16px; built-up area. A set of springs develops sufficient pressure for the copper contacts on the cathode bar. Thanks to the higher electric current conductivity of copper contacts, the socket's size is more compact. The socket can also be equipped with inner cooling and a protective cover. Sockets with even higher transmission can be supplied after consultation.

|

Type Designation |

Current conducted (A) |

Number of Contact Pairs |

|

A-0010-18-01 |

1,500 |

2 |

|

A-0010-18-02 |

2,250 |

3 |

|

A-0010-18-03 |

3,000 |

4 |

Material: Copper (Cu), Steel Cover

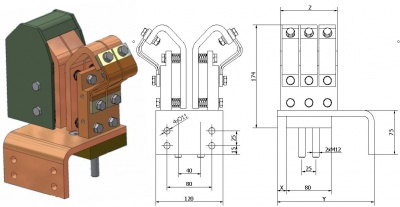

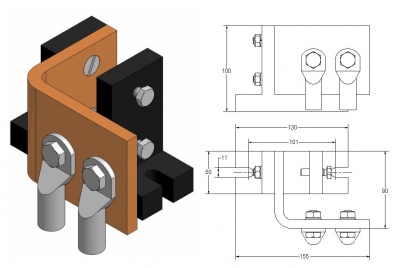

Knife-Type Pneumatic-Pressure Socket

This socket type is characterised by its compact size. A pneumatic cylinder develops sufficient pressure for the copper plate contacts. 6-bar compressed air should be supplied to the socket. Thanks to its 16px; contact surface, the socket's electric current transmission is high in relation to its size. This socket type is equipped with an inner cooling system helping to dissipate heat developed by the conduction of electrical current. For manual lines, the socket is supplied with a bypass valve for opening and closing the socket. This socket type allows the conduction of current up to 6,000 A. For automatic lines, the socket is supplied with limit switches on the pneumatic cylinder; these switches provide the control system with information on the socket's condition (closed/open).

Type Designation: A-0010-13-15

Material: Copper (Cu), Steel Cover

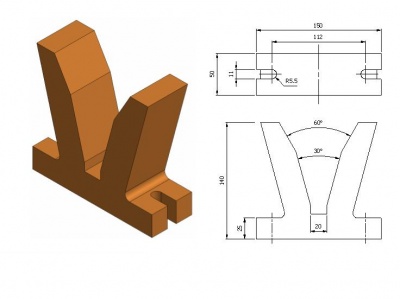

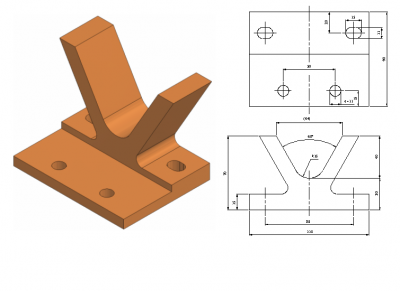

Wedged Cathode Socket

The wedged cathode socket is used for seating cathode bars with wedge-like cross-section shape ends. This kind of shape ensures precise seating and good contact of the cathode bar with the socket. A copper pad with a bent end is placed under the socket to allow connection of the electric power supply. Thanks to its simple shape, the socket is very easy to clean.

Type Designation: A-0010-04

Material: Bronze

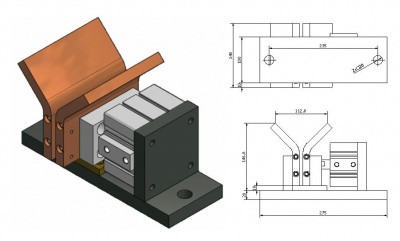

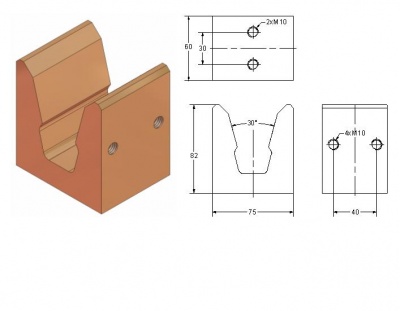

Bar Cathode Socket

The bar cathode socket is used for seating plating drums whose ends terminate in circular bars of the same diameter as the socket bottom convex shape radius. The socket is characterised by its simple shape; however, the contact area of the bar with the socket is 16px;er than that of the wedged socket and, consequently, electric current transmission is also 16px;er. The advantage of this socket consists in the excellent stability of the plating drum position on the bath. This is ensured by the layout of two sockets on one side and one socket on the other side (three-point contact).

Type Designation: A-0010-07

Material: Bronze

Knife-Type Anode Socket

This socket type is used for fixing anode bars to the bath. In most cases, anode bars are not as frequently handled as cathode bars; therefore, the design of the sockets is simpler and the dimensions 16px;er due to less electrical current conducted (the electrical current flows through two anode bars). These sockets are used for anode bars with knife-like ends; screws positioned on one side place pressure on the contact faces.

Type Designation: A-0010-07

Material: Bronze

Knife-Type Anode Socket

This socket type is used for fixing anode bars to the bath. In most cases, anode bars are not as frequently handled as cathode bars; therefore, the design of the sockets is simpler and the dimensions 16px;er due to less electrical current conducted (the electrical current flows through two anode bars). These sockets are used for anode bars with knife-like ends; screws positioned on one side place pressure on the contact faces.

Type Designation: A-0010-12

Type Designation: A-0010-12

Material: Bronze

Foto: